Maintenance, commissioning and field services

Gemco boasts wide experience of maintenance on Gas Turbines (A, B, C and C2 inspection) plus Steam Turbines, Hydropower Plants , Generators, Motors, and Pumping Stations.

HOW WE WORK

Gas Turbine Maintenance

- Disassembly and assembly with turbine noise enclosure instruments

- Taking all measurements before disassembly of turbine and generator

- Turbine rotor disassembly and assembly

- Gas turbine rotor and stator maintenance

- Turbine rotor chemical cleaning processes or sand blasting of blades with dry ice

- Eye control and maintenance of combustion chambers, change of ceramics and nozzles (burner)

- Disassembly, maintenance and assembly of turbine valves

- Hot-Gas Path maintenance

- Fixed-moving wing change

- Control and maintenance of turbine bearings

- Crack tests

- Compressor section maintenance

- Air Intake section maintenance and filter changes

- Turbine coupling adjustment

- Oil tank, oil pump and oil heat exchanger maintenance, oil changes

- Maintenance of auxiliary systems

- Dismantling and installation of turbine insulation

HOW WE WORK

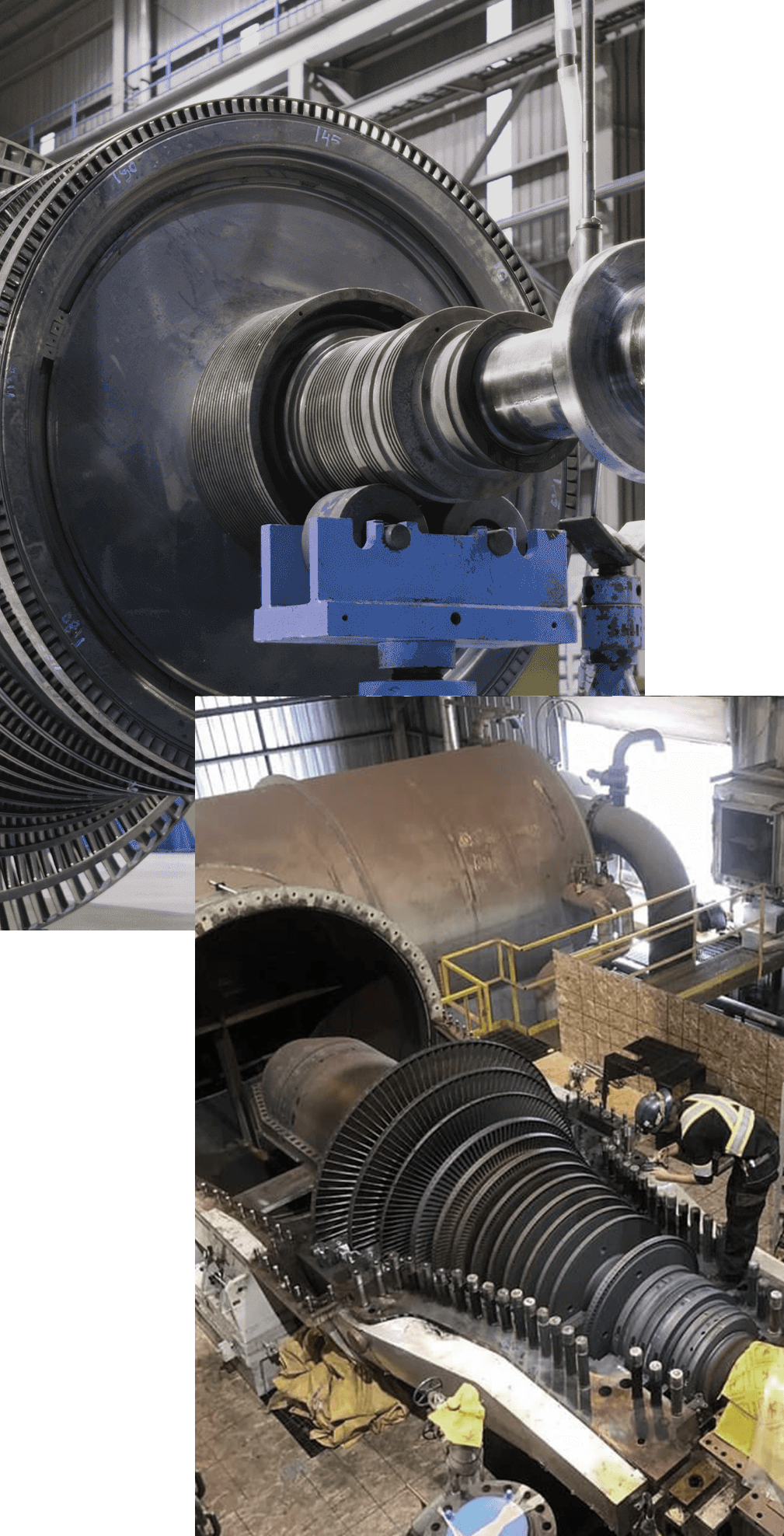

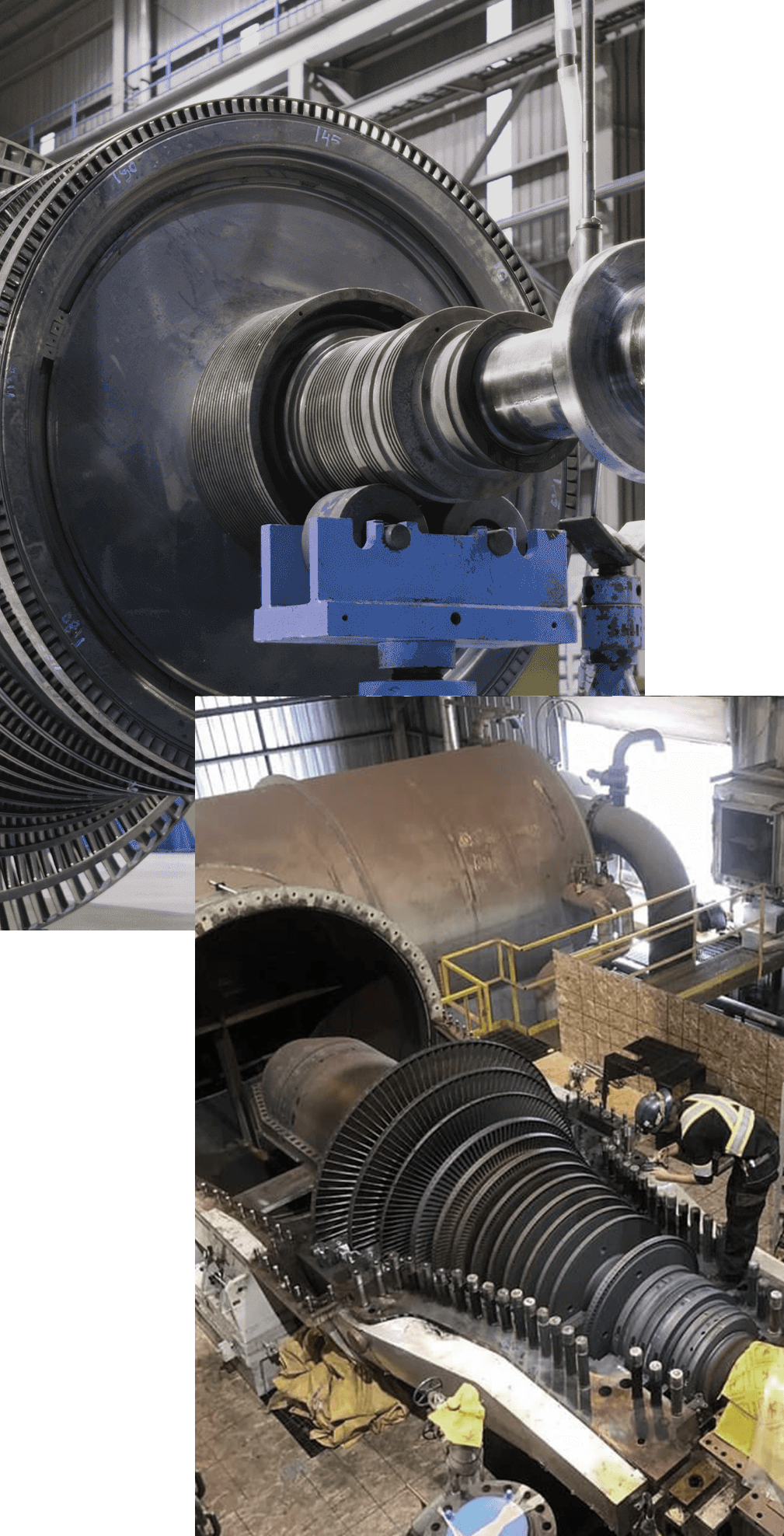

Steam Turbine Maintenance

- Disassembly and assembly of high pressure, medium pressure and low pressure rotors

- Maintenance of high pressure, medium pressure and low pressure stages

- Main lubrication gear unit maintenance

- Disassembly and maintenance of steam sealing bodies

- Turbine outer and inner casing axial and radial wedge control, making it operational

- Turbine bearing control, NDTs and maintenance

- Application of NDT to rotor blades

- Diameter control of gland vapor sealing system labyrinths and replacement if necessary

- Checking the bearing oil sealing labyrinths and replacing them with new ones if necessary

- Testing and assembling of gland and turbine casings; checking and joining between blueprint halves if necessary

- Bed Blueprint tests and acclimatization, shim settings

- Performing and evaluating rotor lead test, making radial and axial adjustments, assembling, keeping radial and axial stator-rotor clearance protocol values

- Disassembly, maintenance, compensator controls, installation of crossover piping

- Inspection and maintenance of lubricating oil and lifting oil unit

- Main oil tank maintenance

- Turbine oil change and filtration of oil with mobile filtration unit

- Maintenance of fixed and movable wings

- Turbine coupling adjustment

- Commissioning

- Troubleshooting vibration problems

- Balancing on the rotor site

- Sandblasting of rotor and movable fixed blades

HOW WE WORK

Steam Turbine Maintenance

- Disassembly and assembly of high pressure, medium pressure and low pressure rotors

- Maintenance of high pressure, medium pressure and low pressure stages

- Main lubrication gear unit maintenance

- Disassembly and maintenance of steam sealing bodies

- Turbine outer and inner casing axial and radial wedge control, making it operational

- Turbine bearing control, NDTs and maintenance

- Application of NDT to rotor blades

- Diameter control of gland vapor sealing system labyrinths and replacement if necessary

- Checking the bearing oil sealing labyrinths and replacing them with new ones if necessary

- Testing and assembling of gland and turbine casings; checking and joining between blueprint halves if necessary

- Bed Blueprint tests and acclimatization, shim settings

- Performing and evaluating rotor lead test, making radial and axial adjustments, assembling, keeping radial and axial stator-rotor clearance protocol values

- Disassembly, maintenance, compensator controls, installation of crossover piping

- Inspection and maintenance of lubricating oil and lifting oil unit

- Main oil tank maintenance

- Turbine oil change and filtration of oil with mobile filtration unit

- Maintenance of fixed and movable wings

- Turbine coupling adjustment

- Commissioning

- Troubleshooting vibration problems

- Balancing on the rotor site

- Sandblasting of rotor and movable fixed blades

HOW WE WORK

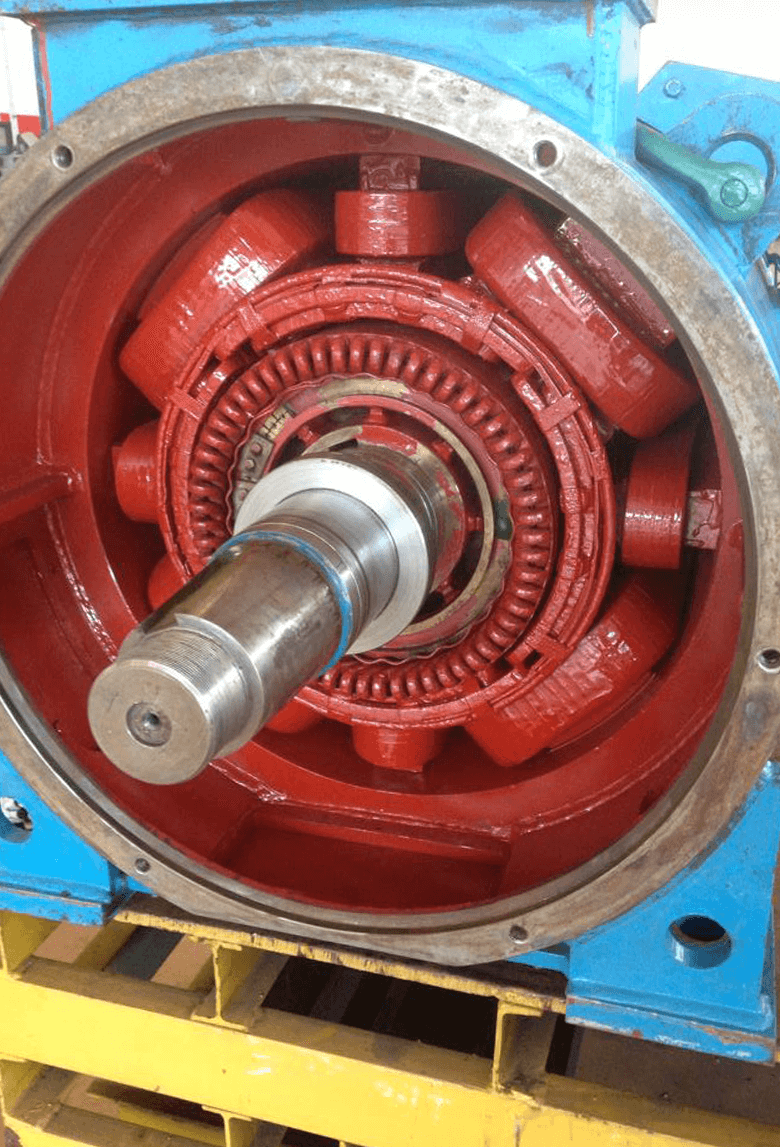

Generator and Motor maintenance

- Manufacturing of rotor disassembly apparatus

- Rotor disassembly and assembly

- Generator rotor and stator chemical cleaning processes

- Retaining ring disassembly and assembly, insulation control

- Dismantling, maintenance and pressure tests of generator coolers

- Control and maintenance of generator bearings

- Generator warning system disassembly and maintenance

- Generator, stator winding control, replacement and maintenance

- Control and maintenance of rotor and stator insulation paints

- Maintenance and installation of sealing rings

- Maintenance of auxiliary systems

- Megger test

Through our partners, with the support of our technical staff, we can design and manufacture electric motors and generators, variable speed drives, industrial automation and control systems, as well as grid power systems and power quality systems. Our cutting-edge products, process models and automation solutions contribute significantly to ensuring a tangible return on investment for our customers.

We work closely with OEMs and end users in order to identify the best solutions for each phase of the project, from initial design to start up and commissioning.

Many customers rely on us for their feasibility studies related to the development of new industrial processes or applications. With over a century of experience behind us, we are the ideal partner for large turnkey automation projects, revamping and upgrade activities, transfer or change of production and we are able to guarantee the perfect integration of our systems with those already existing in your plant.

HOW WE WORK

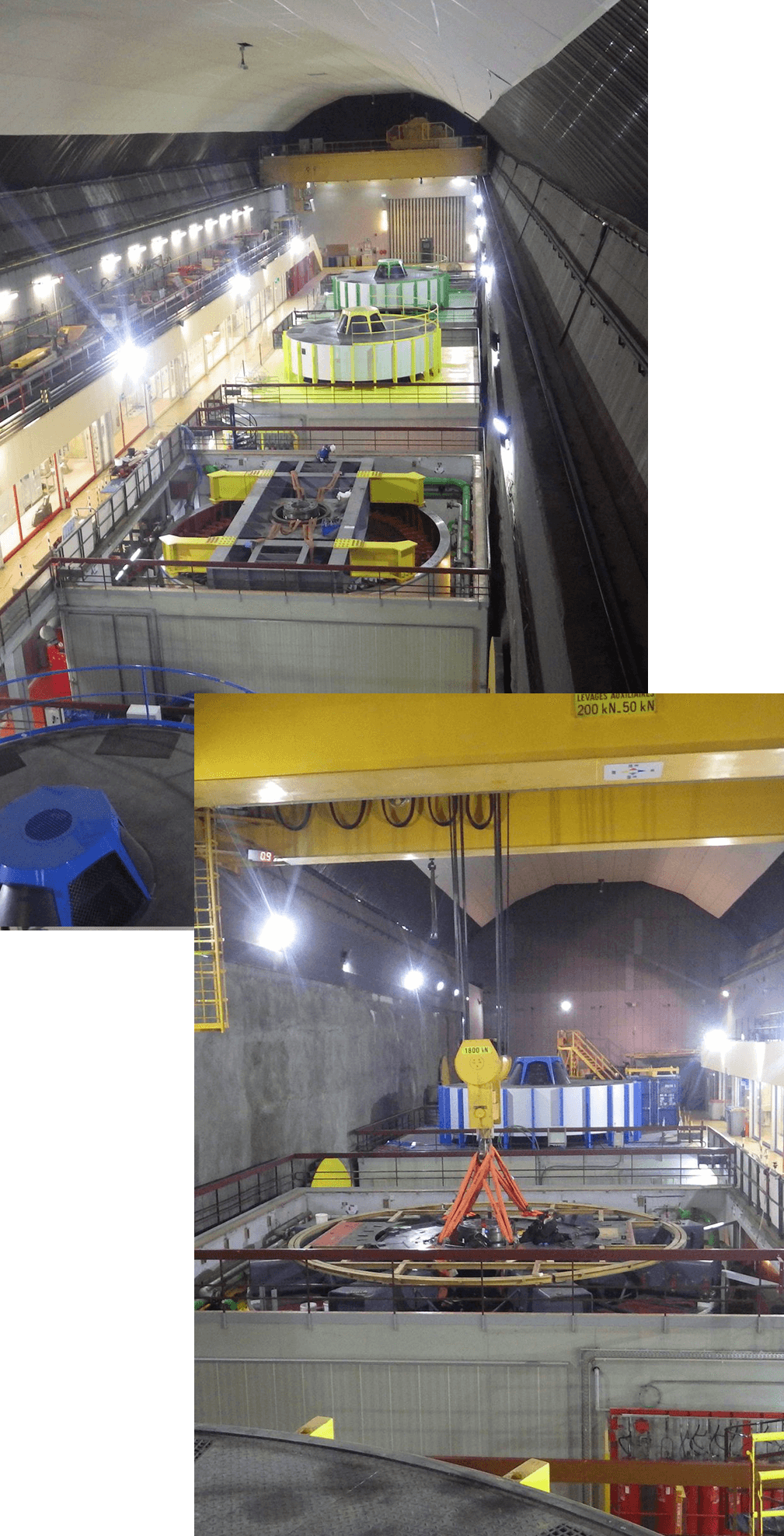

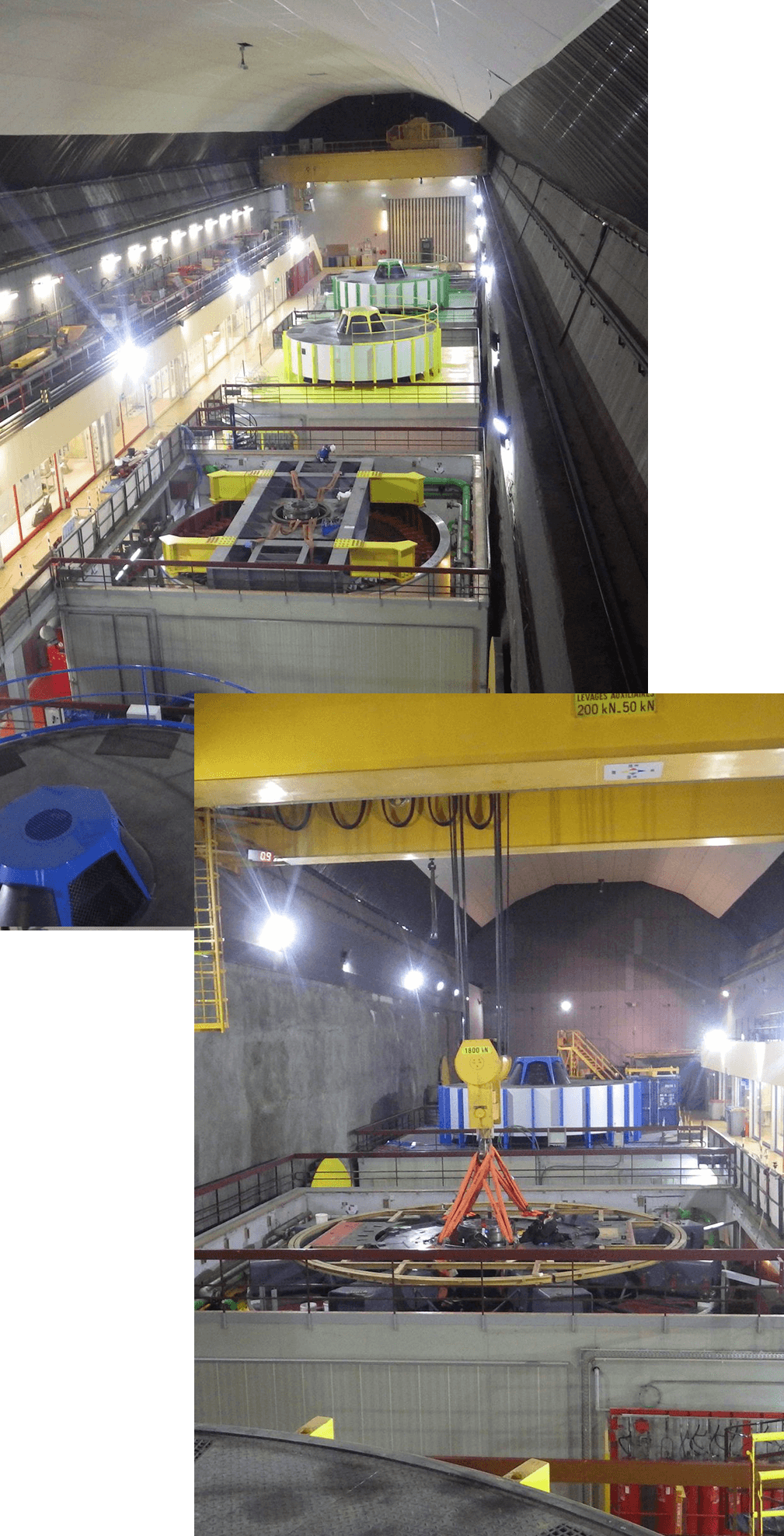

Hydropower Plant Maintenance

- Electromechanical equipment

The electromechanical equipment of an HPP is its heart, which allows failure-free power generation, depending on the correct handling of turbines, electrical equipment in general and the power lines, generators, equipment to regulate, control, protect, automate and auxiliary systems. Equipment monitoring and operation control allow to establish, not only an intervention service, but also maintenance including predictive maintenance to maximize the availability and profitability of the hydropower plant. The execution of services in "multi-technology" brings innovation along the entire value chain to ensure that the plants produce as much electricity as possible and, above all, in optimal conditions to maximize plant life, using the latest technologies for both repair and predictive maintenance. - Maintenance of electromechanical installations

GEMCO ensures maintenance services that are grouped according to the activity performed and the chronological order of their implementation. In his most primary form, maintenance is classified into planned preventive and unplanned corrective. - Preventive maintenance of electromechanical installations

Preventive maintenance occurs when actions are carried out at predetermined intervals or also according to prescribed agreements aimed at reducing the probability of failure and/or degradation of an element's performance. One or more inspection schedules are normally carried out periodically, for its safe operation, adjustments, repairs, analysis, lubrication, calibration of the turbine, generator, transformer and gates as well as general cleaning of the electromechanical equipment installed, pipes and accessories inside the power house, visual inspection of electrical connections, switchboards and cable conduits, heating generator, inspection and cleaning of bearings and butterfly valve. - Corrective maintenance of electromechanical installations

Unplanned corrective maintenance is a set of activities to repair and replace deteriorated elements, which is performed when failure occurs. It is regularly applicable to complex systems, such as electronics, where failures are sometimes impossible to predict and when very long recovery times occur. Corrective maintenance is an unscheduled maintenance action, basically composed of unpredictable repair needs that cannot be planned in advance or scheduled on the basis of occurrence at a particular time.